PHASED ARRAY ULTRASONIC TESTING (PAUT)

An array transducer is simply one that contains a number of separate elements in a single housing, and phasing refers to how those elements are sequentially pulsed. A phased array system is normally based around a specialized ultrasonic transducer that contains many individual elements (typically from 16 to 256) that can be pulsed separately in a programmed pattern. These transducers may be used with various types of wedges, in a contact mode, or in immersion testing.

that contains many individual elements (typically from 16 to 256) that can be pulsed separately in a programmed pattern. These transducers may be used with various types of wedges, in a contact mode, or in immersion testing.

APPLICATIONS

Weld inspection – Structural / Piping

Corrosion Mapping

High Temperature PAUT up to 200°C (Weld Inspection / Corrosion Mapping)

PAUT in lieu of Radiography Testing (ASME Sec VIII, API 620, ASME B31.3, B31.1)

COMPANY’S CREDENTIALS/APPROVALS/ACCREDIDATION:

IS/IEC – 17025

DNV Validation Approval for Piping

DNV Validation Approval for Structural

SAC-SINGLAS

PERSONNEL QUALIFICATION

PCN,CWSIP,ASNT Level 2/3

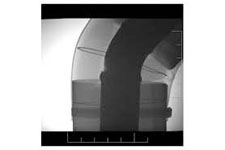

TIME OF FLIGHT DIFFRACTION (TOFD)

Although time-of-flight diffraction (TOFD) can be used for a variety of applications, its primary use is rapid weld testing of circumferential and axial weld seams, also known as perpendicular TOFD scanning. Since the introduction of TOFD in the 1970s, the use of this reputed reliable non destructive testing technique has steadily increased. Manual execution is possible with TOFD, however, it is most commonly performed in combination with a recording device, that is, an encoder or industrial scanner. To achieve code compliance in North America, TOFD is often coupled with pulse-echo or phased array techniques in order to cover the root and cap regions of the weld.

1970s, the use of this reputed reliable non destructive testing technique has steadily increased. Manual execution is possible with TOFD, however, it is most commonly performed in combination with a recording device, that is, an encoder or industrial scanner. To achieve code compliance in North America, TOFD is often coupled with pulse-echo or phased array techniques in order to cover the root and cap regions of the weld.

APPLICATIONS

Weld inspection – Structural / Piping

ToFD in lieu of Radiography Testing (ASME Sec VIII, API 620, ASME B31.3, B31.1)

COMPANY’S CREDENTIALS/APPROVALS/ACCREDIDATION:

IS/IEC – 17025

SAC-SINGLAS

PERSONNEL QUALIFICATIONS

PCN, CSWIP, ASNT Level 2/3

ALTERNATING CURRENT FIELD MEASUREMENT TESTING (ACFM)

ACFM® is an electromagnetic inspection technique that introduces an alternating current into the surface of the component to detect surface-breaking cracks. The presence of a crack disturbs the electromagnetic field and the return signal is instantaneously converted by advanced mathematical techniques, so that the operator is alerted to the presence of a defect. Immediate defect sizing and recording is a major benefit compared to alternative NDT methods.

instantaneously converted by advanced mathematical techniques, so that the operator is alerted to the presence of a defect. Immediate defect sizing and recording is a major benefit compared to alternative NDT methods.

APPLICATIONS

Marine offshore Structures/ Offshore Platforms/Rigs/Semi Sub Rigs/ Barges

It requires less cleaning compared to MPI/PT/ECT

When data requires to keep for records/re review/cross check

No need to remove paint / Fast method

COMPANY’S CREDENTIALS/APPROVALS/ACCREDITATION

IS/IEC – 17025

SAC-SINGLAS

PERSONNEL QUALIFICATIONS

CSWIP, ASNT Level 2

OPEN VISION

Corrosion under insulation (CUI) is the corrosion of piping and vessels that occurs beneath insulation as a result of water penetration. The water can come from rain water, leakage, deluge system water, wash water, or sweating from temperature cycling or low temperature operation such as refrigeration units.

Unfortunately, because the corrosion is hidden under the insulation, CUI tends to remain undetected until the insulation is removed for inspection or when leaks occur. CUI is a common problem across many industries, including refining, petrochemical, power, industrial, onshore and offshore industries.

INSPECTION METHODS

Long Range UT

Computed Radiography (CRT)

Digital Radiography (DRT)

Profile Radiography

Real Time Radiography (Open Vision)

PERSONNEL QUALIFICATIONS

API Piping Inspector (API 570)

TRACK RECORD

Exxom Mobil (Open Vision)

Shell Eastern Petroleum, Bukom Terminal (Open Vision, Profile Radiography

MISC Malaysia (Computed Radiography)

COMPUTER RADIOGRAPHY TESTING (CRT)

Computed Radiography (CR) is the production of a digital image by using a Phosphor Imaging Plate (IP) in place of conventional film.The Image (storage) Plate (IP) is exposed with X-ray or Gamma radiation, which causes the IP phosphor layer in the plate to store the X-ray image. During the reading process of the plate in the scanner, a focused laser beam triggers the release of the stored image data in the form of visible light. The emitted light is detected, captured, and converted into electrical signals which are digitized and finally displayed as a digital image on the PC monitor. The internal in-line eraser purges the residual data from the IP, which is then ready for the next exposure.

triggers the release of the stored image data in the form of visible light. The emitted light is detected, captured, and converted into electrical signals which are digitized and finally displayed as a digital image on the PC monitor. The internal in-line eraser purges the residual data from the IP, which is then ready for the next exposure.

APPLICATIONS

Corrosion, Pitting in Insulated Pipelines

Process Pipelines Corrosion Findings

No need to remove insulations

Weld Inspection for Quick Review Profile Radiography for Corrosion Findings

COMPANY’S CREDENTIALS/APPROVALS/ACCREDITATION

ISO/IEC – 17025

SAC-SINGLAS

PERSONNEL QUALIFICATIONS:

NDT Level II / PCN

TRACK RECORDS:

EMAS Offshore, MISC Malaysia, Cochin Refineries India

SembCorp

DIGITAL RADIOGRAPHY (DRT)

An X-ray beam is focused at the imaging detector. In medical applications the anatomy of the patient that needs to be examined is positioned in front of the detector. As the beam passes through the anatomy and hits the detector it is filtered by a scintillator.

The scintillator comes in different substrate materials and in this application it is most often Cesium Iodide (CsI) or Gadolinium Oxysulphide or Gaddox (GdOS). The scintillator emits light from exposure to the X-ray beam and is deflected by a mirror on to a lens which focuses the light onto the 9 or 16 Megapixels of the CCD dependant of the platform of IDC technology.

APPLICATIONS

Corrosion, Pitting in Insulated Pipelines

Process Pipelines Corrosion Findings

No need to remove insulations

Weld Inspection for Quick Review

Profile Radiography for Corrosion Findings

PERSONNEL QUALIFICATIONS

NDT Level II / PCN

SCAR RADIOGRAPHY TESTING (SCAR RT)

Small Controlled Area Radiography (SCAR) SCAR-a directional gamma radiography system for use in areas congested with workers, confined spaces, or where radiation output must be kept to an absolute minimum so not to disrupt normal operations. SCAR utilizes a compact exposure device with built-in collimation to enhance the ability for radiographic inspection to be performed more safely and with equal, if not higher, levels of productivity compared to traditional gamma exposure devices. SCAR allows for smaller restrictive barricades, eliminates flash dose to radiographic personnel, and may increase the overall productivity of radiography crews when utilized in congested areas where increased manpower is present, such as plant shutdowns.

performed more safely and with equal, if not higher, levels of productivity compared to traditional gamma exposure devices. SCAR allows for smaller restrictive barricades, eliminates flash dose to radiographic personnel, and may increase the overall productivity of radiography crews when utilized in congested areas where increased manpower is present, such as plant shutdowns.

APPLICATIONS OF SCAR RADIOGRAPHY TESTING (SCAR RT)

Radiation Barricade distance only 5M Radius

No need to Stop other activities

Can be used with Se75 Source which gives high quality Radiographs

COMPANY’S CREDENTIALS/APPROVALS/ACCREDIDATION

ISO/IEC – 17025

SAC-SINGLAS

PERSONNEL QUALIFICATIONS FOR SCAR RADIOGRAPHY TESTING (SCAR RT)

NDT Level II / PCN

TRACK RECORDS

TIMAS OFFSHORE, EMAS Offshore, Keppel Group

Sembawang Shipyard